Industrial Products

RePG Scalable Industrial Products and Systems for Off-Grid Energy Needs in Light and Heavy Industry, Workplaces, Buildings, Hotels and Public Institutions

RePG produces devices that produce energy between 20 kWh and 1 mWh by using air, more or less intense waste heat (hot water, steam, gas, geothermal, sunthermal, day-heat) in industrial environments. The devices produce electricity and water by using the intense waste heat in the industry (Chimney, Boiler, Engine or stove, etc.), hot water, geothermal, steam and heat generated by machine components.RePG Technology can recover 10% -20% of the waste energy as electrical power by using all waste heat sources at 35°C and above. Traditional Industrial model waste heat recovery systems require a minimum heat/energy source above 250°C and a cost payback period of 12 - 15 years. But now there is RePG!

Get to Know the Industrial Products!

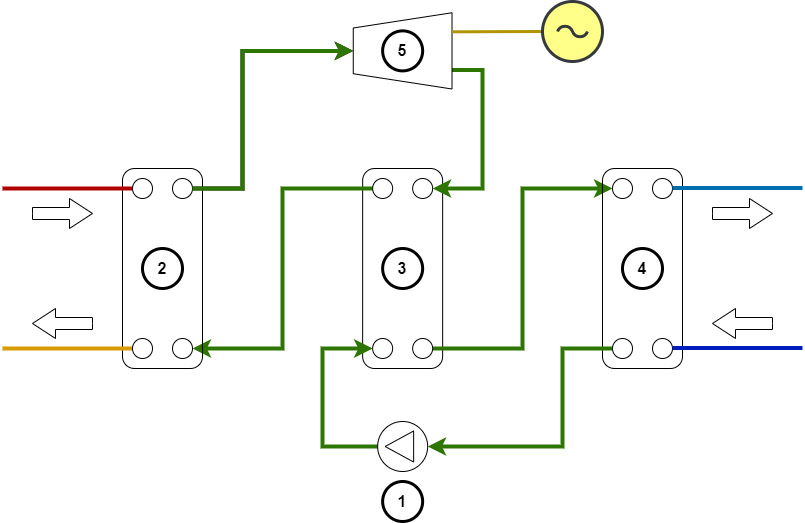

Industrial Type RePG Working Principle

- Pump: It is used for pressurizing the RePG fluid in the system.

- Evaporator: It is used to transfer heat energy from heat sources such as factory chimneys, geothermal sources, sun thermal systems to the RePG fluid.

- Recuperator: It is used to provide heat transfer between the hot gas at the turbine nozzle and the cold fluid pressurized by the pump while increasing the overall efficiency of the system.

- Condenser: While ensuring the cooling of the gas at the turbine nozzle, it creates a useful heat. This energy can be used in the water phase in heating systems.

- Turbine: It is used to generate electrical energy with high efficiency during the expansion of the RePG fluid.

Discover RePG Industry Models

Factory chimneys generate energy using waste heat or sun thermal. Minimum chimney temperature is 50 °C +, Minimum sun thermal temperature is 35 °C +

Industry Type I

25 – 100kWe

Industry Type II

100 – 250kWe

Industry Type III

250 – 500kWe

Industry Type IV

500 – 1mWe

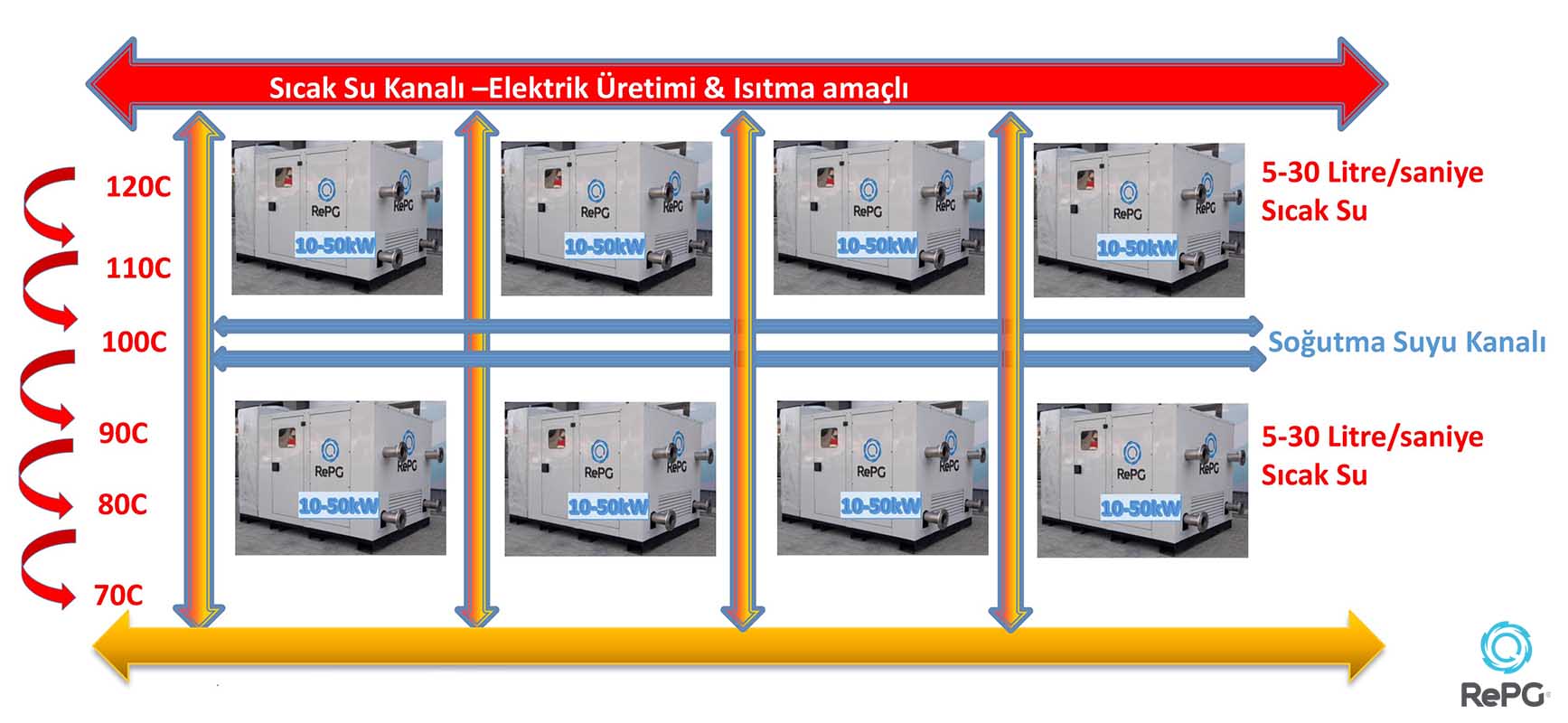

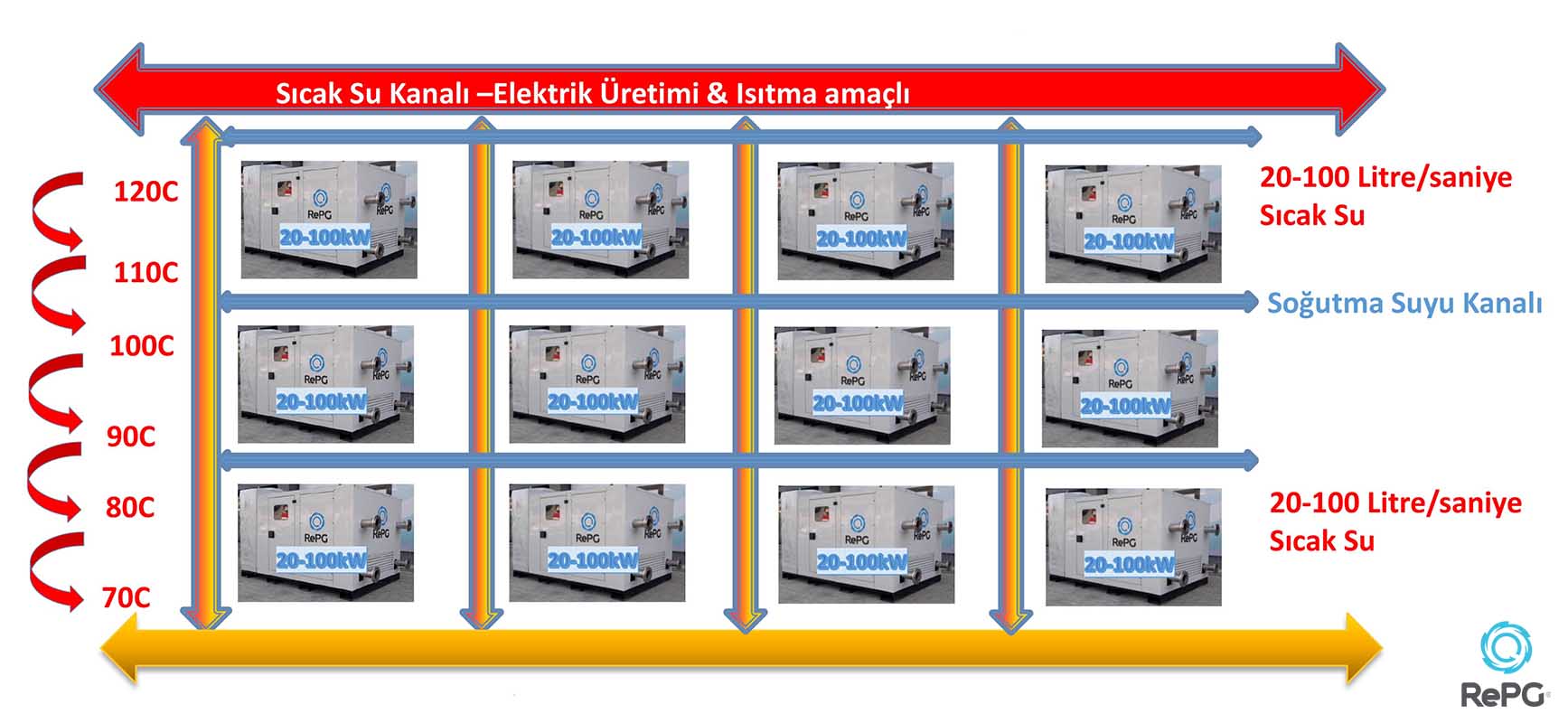

RePG Industrial Type Modular Applications

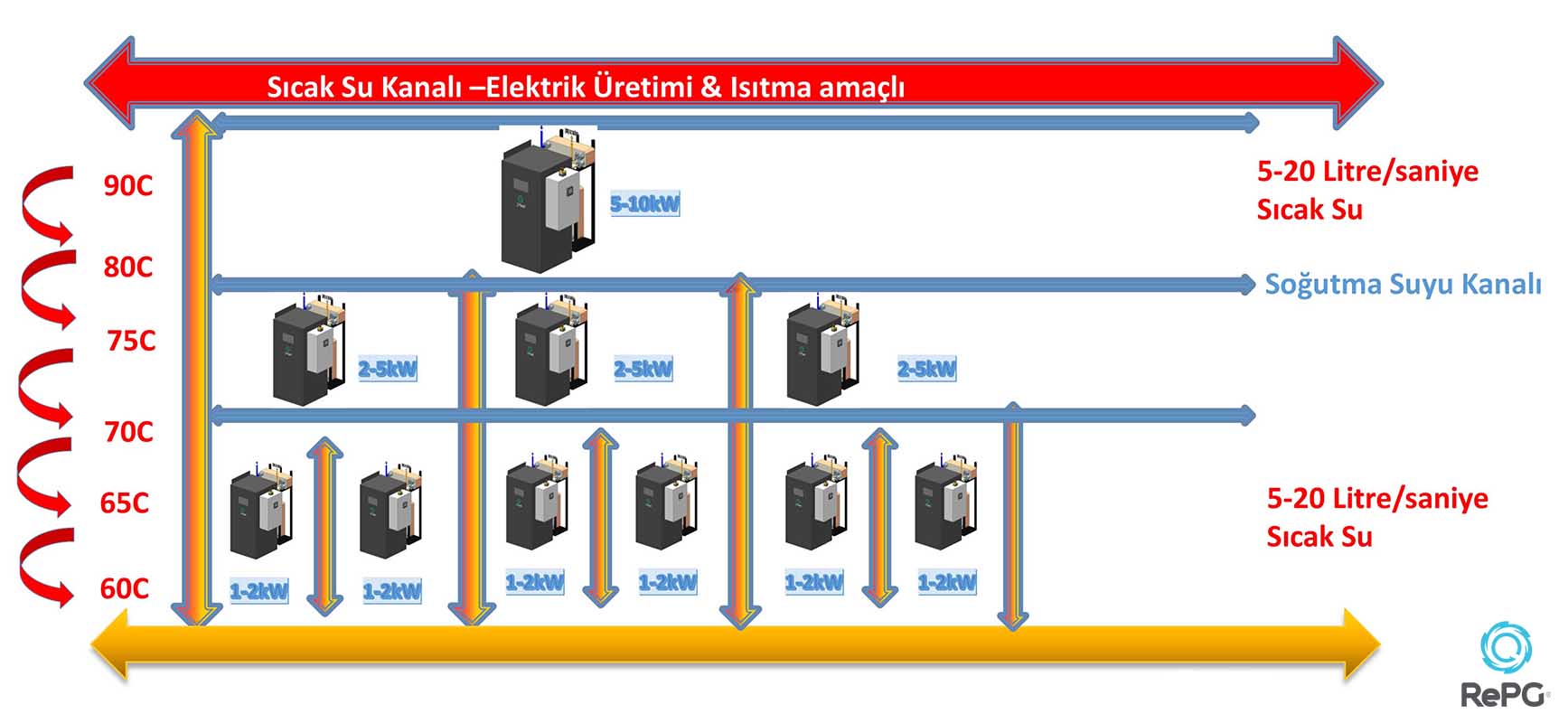

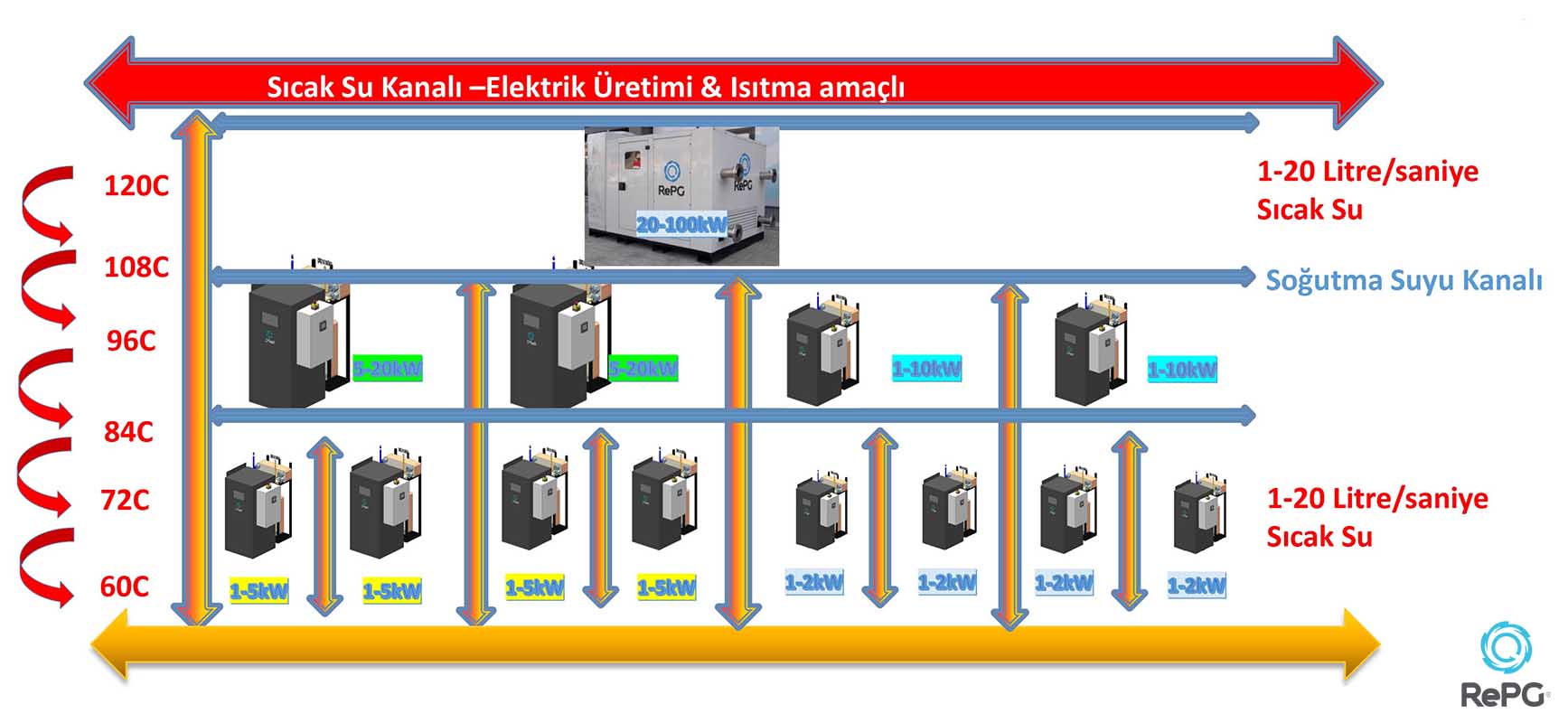

RePG Industrial Products can be connected both in series and in parallel, and MACRO modules and MICRO modules can work together as a compatible system.

Macro Systems

Micro Systems

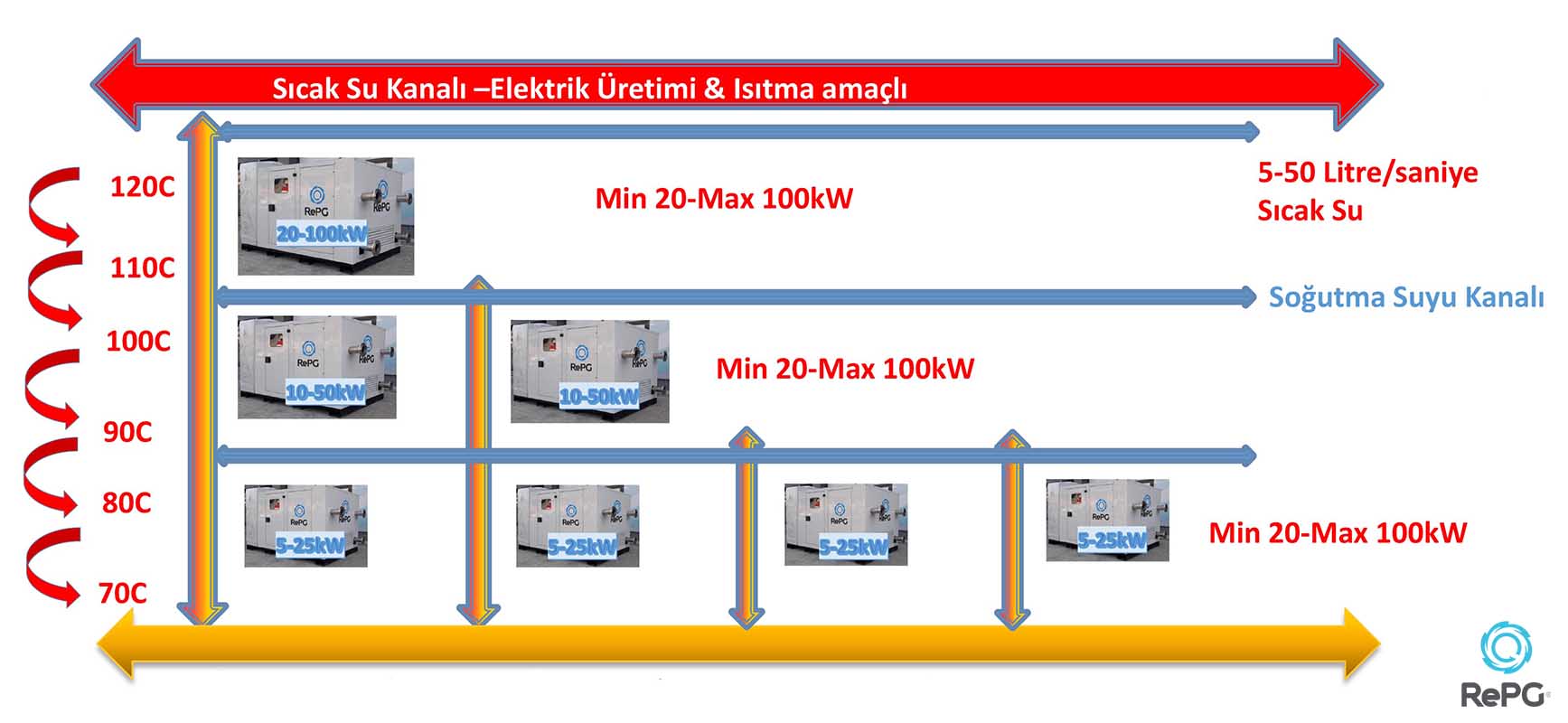

Micro and Macro Combined Modular System

Single Macro + Multiple Micro Modular System

1x100kW, 2x20kW, 2x10kW, 4x5kW and 4x2kW

Energy System

Total of 188kW Connection in Parallel & Series

- With 5 Different Systems, and the Total of 1 Macro and 12 Micro Modules is 188kW, min. 1kW of energy can be produced.

- With a total of 12 Micro Modules, min. 1kW and max . 88kW of Net Energy is produced.

- With 1 Macro Module, min. 20kW and max. 100kW of Net Energy is produced.

Micro and Macro are Integrated

Modular System

Single Macro + Multi Micro

Modular System

1x100kW, 2x20kW, 2x10kW, 4x5kW and 4x2kW

Energy System

Total of 188kW Connection in Parallel & Series

- With 5 Different Systems, and the Total of 1 Macro and 12 Micro Modules is 188kW, min. 1kW of energy can be produced.

- With a total of 12 Micro Modules, min. 1kW and max . 88kW of Net Energy is produced.

- With 1 Macro Module, min. 20kW and max. 100kW of Net Energy is produced.

- The modular structure can be designed with Hot Water Flow Rate and Temperature.

- External weather conditions, cooling water, and the working time of the systems determine energy production.